The main technical parameters

1.power:220V 60HZ 1.0KW

2.servo driver:INOVANCE IS-500PS5R5I

3. servo motor:ISMH1-75B-30CB-V131X

750W 200V 4.6A 3000R/M

4.PLC:Delta DVP-12SC11T

Operating instructions:

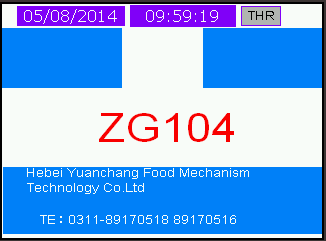

After connect with the power then will show as following screen:

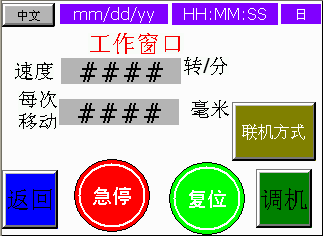

Clik any button on screen then will enter into working manual:

1.Working Manual:

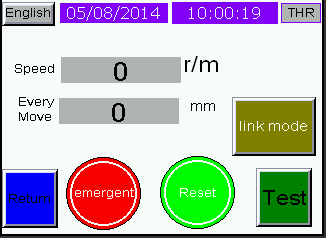

After Hanging machine connect with stuffer by electric cable, it will automatic in connect state,if did not want this,you can press the “Emergent”button On screen.

According to the distence between the two hanger to Setting the rotate distance in per time,pay attention to that the unit is mm.

Then according to the work speed of stuffer to setting suit speed on screen.

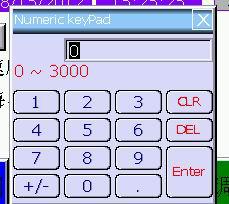

Speed and distence setting methods are as following,such as the speed ,touch the enter speed number place on screen then will show an keybord(as below picture show)

After setting suit speed then press ”Enter” button is ok.

Now it is ok for connect with the stuffer ,in practice,you can change suit speed according to the real filling speed

button function declaration

If the hanger have emergency situation ,press the

“emergent”button,it will stop immediately.Attention,this buttom can also use as stop the connect between two machines.

After stuffer stopped,press this “Reset” button,hanging machine will automaticly to search the beginner position of the next group.

Pressure the ”Ruture”,it will back to the former screen.

This button”Test” is using for test machine when machine is not in real work,press it then will enter debug machine screen.

|